Maximize injection, production and recovery rates

Current frac and pack technologies are prone to integrity and stability issues that negatively impact production and recovery. FUSION technology provides you with the well integrity critical to inject and produce at the ultra-high rates required to improve well economics and increase EUR.

Avoid proppant pack washout, voids and loss of wells

The lack of closure stress within the annulus means that the compressive forces required to bond conventional resin-coated proppant or hold the pack in place are not present. The result is a proppant pack with low integrity and poor stability that is prone to proppant washout which can lead to voids, channels and in worst case scenarios the complete loss of the injector well.

Inject and produce at the rates you want

With FUSION technology, E&P operators are no longer required to limit water injection rates to protect the integrity of the annular pack and safeguard the well. This removes previous unnecessary limitation which reduced production and injection rates and the estimated ultimate recovery (EUR) from the reservoir.

Create a high integrity annular pack in low compressive environments

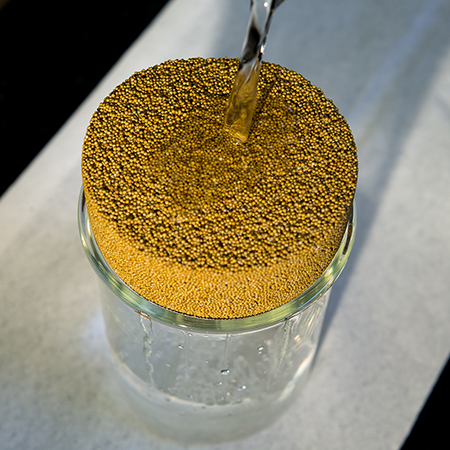

FUSION technology features durable, high conductivity ceramic proppant with a proprietary resin coating which enables controlled bonding of the proppant pack using a unique chemical-activator.

The chemical-activated bonding process forms a strong, flexible bond without compression even in low temperature environments to create a high integrity pack that withstands stress cycling to sustain long-term pack integrity.

Evaluate pack integrity and propped fracture height for the life of the well

For additional reassurance, FUSION technology allows you to evaluate the placement and integrity of the proppant pack at any time during the life of the well.

Permanently detectable CARBONRT® inert tracer technology is manufactured into the substrate of every proppant grain. This enables proppant within or near the wellbore to be detected to evaluate pack placement and quality utilizing our propriety evaluation process.

The process can also be used to provide a direct measurement near-wellbore propped fracture height, width and connectivity.

A combination of innovative CARBO technologies

FUSION technology has been created by bringing together a unique combination of innovative and proven CARBO technologies:

- Durable, high conductivity ceramic proppant

- Proprietary coating technology

- Chemical bonding activator

- Inert tracer technology

+1 800 551 3247

+1 800 551 3247 5050 Westway Park Blvd #150, Houston, TX 77041, USA

5050 Westway Park Blvd #150, Houston, TX 77041, USA